CompreDrive

New experimental horizons in solid-state-battery and solid electrolyte research

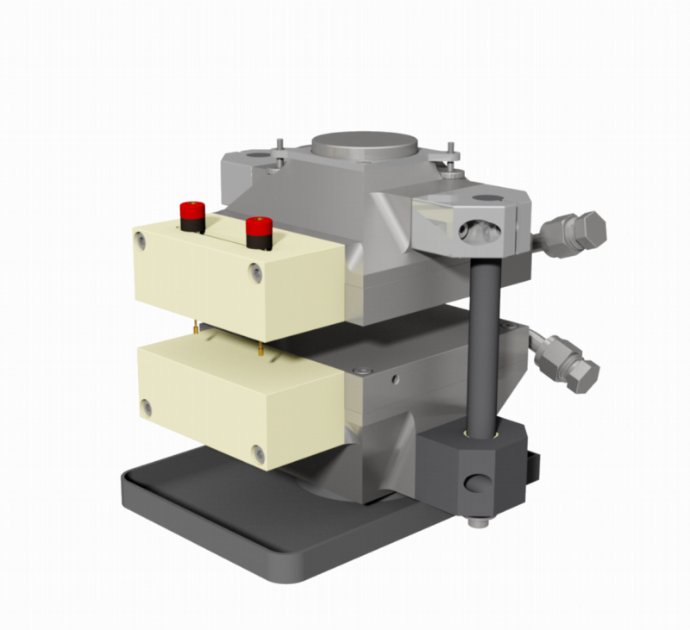

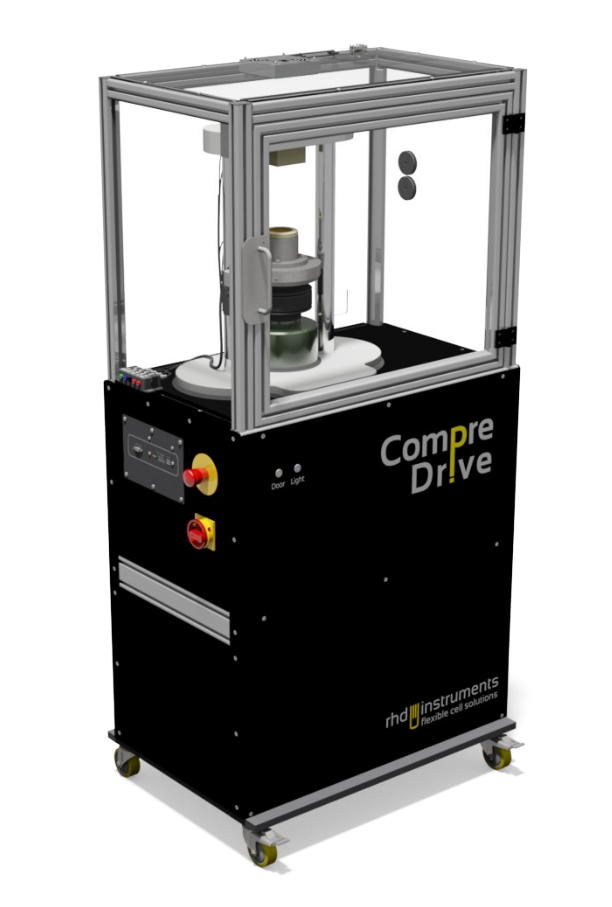

The CompreDrive is an electrochemical laboratory-press designed for solid state electrochemistry research under active force and temperature control.

With the CompreDrive, uniaxial forces up to 75 kN (e.g. 663 MPa @ 12 mm, 1.7 GPa @ 6 mm) can be applied and kept constant on the sample with unprecedented accuracy by the active force regulation system.

Unlike typical active presses the CompreDrive uses an ultra-high resolution servo drive for force regulation instead of a hydraulic system. This allows for high positioning speeds with a minimum step width of <10 nm.

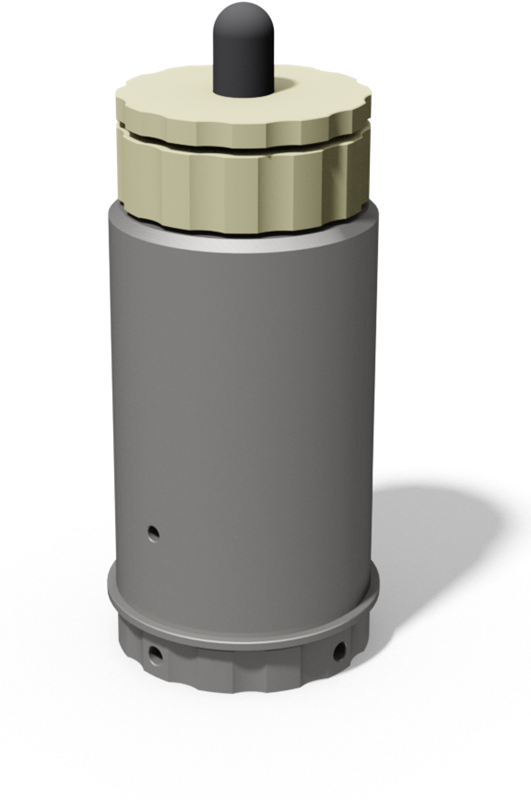

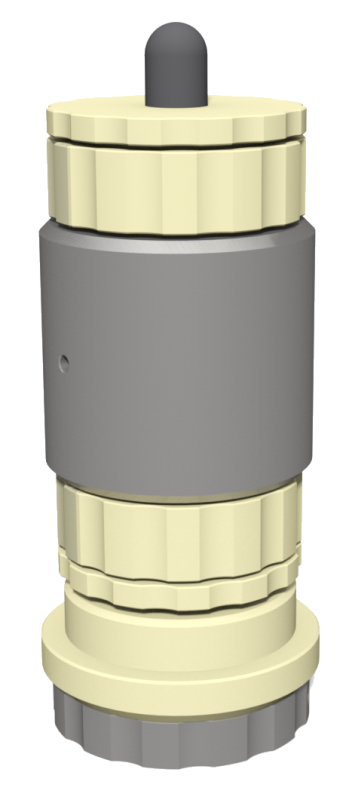

The sample is placed inside a fully sealable, specialized measuring cell (CompreCell), which enables the handling of air-sensitive samples.

Temperature control is achieved by different types of mantles, which are supplied based on your requirements. The CompreDrive hardware supports a temperature range of -40 to +250 °C.

The included software CompreDriveControl allows an interconnection of thermocontroller/analyzer software/CompreDrive, which enables individual, automated procedures.

Up to 75 kN with 0.5% accuracy

Control and adjust the sample pressure with an unmatched precision and resolution

The CompreDrive allows you to precisely adjust and automatically control the mechanical force applied to your sample within a wide range up to 75kN. The force is automatically regulated by the closed loop control system during measurements. The CompreDrive utilizes a high precision servomotor to apply the selected force onto the sample cell's hard-metal plungers. The motor and gear box allow for nanometer scale movements and, thus, for a much finer force control than commonly used hydraulic systems. The applied force is measured directly in line. A closed loop control system drives the motor to keep the selected force constant.

-40 °C to +250 °C

Temperature control and monitoring in line with highest standards

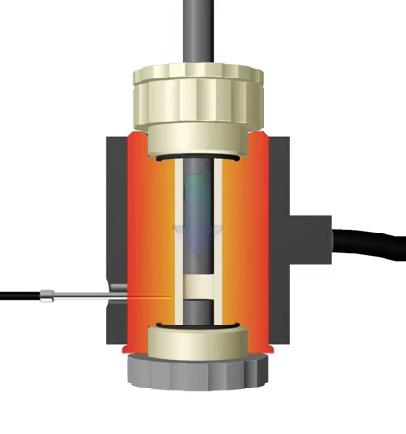

The different available CompreDrive heating units enable adjusting the sample temperature in a range from -40 °C up to +250 °C with a precision of <0.2 °C.

The CompreDrive measuring cells can be equipped with a mantle for either an electrical heating unit or an external circulating thermostat. The mantle can be selected individually for each experiment, giving the maximum flexibility for the researchers specific requirements.

The ability to use an external circulating thermostat allows for cooling the sample down to -40 °C, which is a unique feature for high-pressure solid-state measuring systems.

The temperature is measured very close to the sample with a high-accuracy Pt100 sensor in order to control the true temperature of the sample.

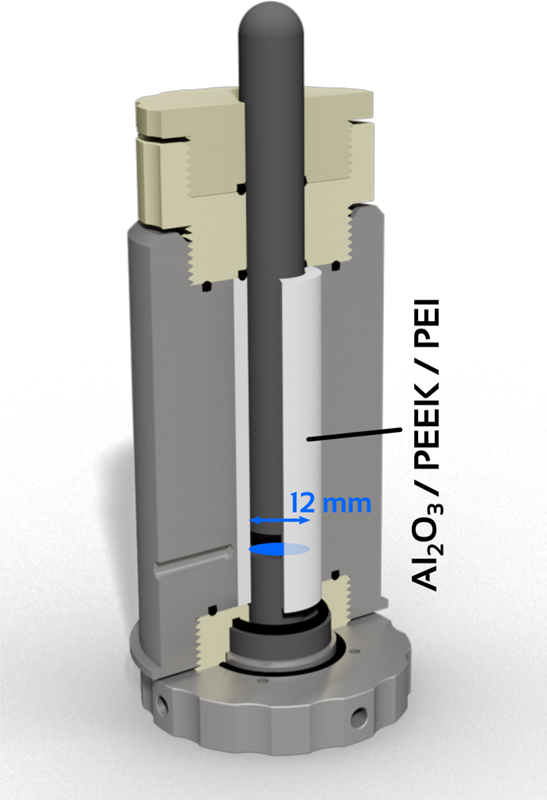

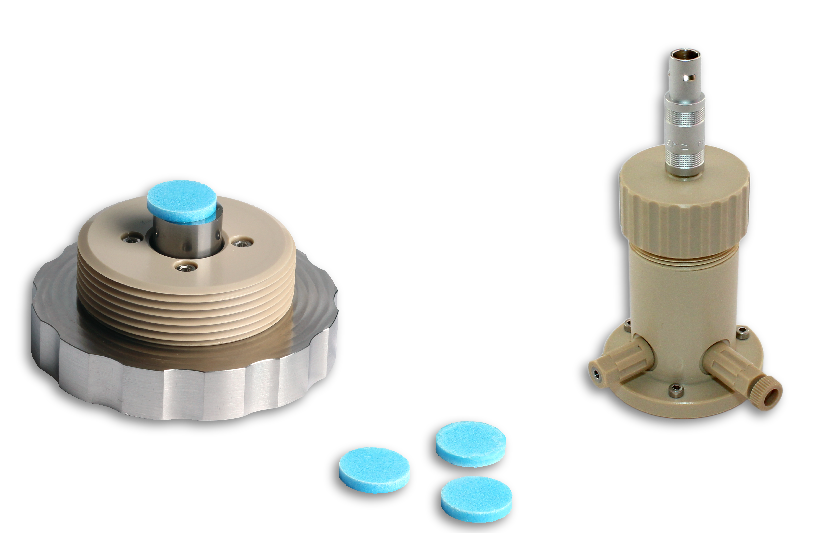

Innovative solid-state cell design

Modular cells allow for out-of-glovebox measurements of sensitive samples

The measuring cells for the CompreDrive are tightly sealed with double-O-ring methods to prevent sample contamination in ambient conditions. Temperature-sensing close to the sample allows for precise and accurate temperature control. Thanks to the innovative design the measuring cell unit can be loaded with your sample inside of a glovebox while the measurement can be performed outside. This saves valuable glovebox space and avoids the need for additional cable feed-throughs which may cause gas leakage or artifacts during your electrochemical measurement. In addition, this concept avoids heating of your glovebox atmosphere. In case of testing an all-solid-state battery, you can easily build up the battery layer by layer, increasing the level of flexibility.

Materials and customization

System design with high-performance materials while keeping it customizable

The CompreDrive and its measuring cells keep only selected materials in contact with your sample but still allow for customization.

All force-bearing components are fully machined from hard-metal to reduce deformations. Electrical insulation is achieved by employing an Al2O3 ceramic, PEI or PEEK insulation insert. All materials are machined to the highest quality and precision standards.

Since each researcher needs to enjoy high-quality and reliable experiments but also has individual ideas and requirements, our philosophy is to find a setup configuration that fulfill your needs 100%. If our standard setup does not satisfy this, please get in touch so we can find a solution that does!

Benefit from automation

Embed the pressure & temperature control directly into your measurement

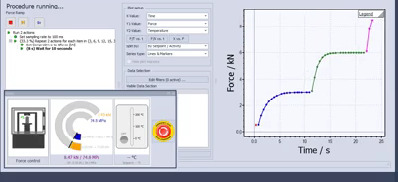

The CompreDrive can automatically run combined pressure and temperature procedures from its CompreDriveControl software. Its abilities can be embedded directly into measuring procedures of many potentiostat and EIS analyzer manufacturers.

The CompreDrive offers various interfaces, either in hardware through digital triggers or through a REST service provided by the CompreDriveControl software. The hardware triggers can be used to advance the pre-programmed procedure to a different pressure/temperature after e.g. an EIS spectrum was measured. They can then signal back to the analyzer that the new setpoint has been reached. The REST service allows directly getting and setting the CompreDrives parameters as well as adjusting the setpoint without pre-programming a procedure, thus allowing for actual data transfer to the analyzer software.

Reproducible sample preparation

Use the CompreDrive for sample preparation, not only for testing

In addition to its abilities in sample characterization the CompreDrive can also be used to prepare samples more reproducible than what was possible with classical laboratory presses. The CompreDriveControl software allows for generating standardized pressure and temperature dependend sample preparation procedures.

Solid-state sample preparation often involves the fabrication of well-defined pellets as well as optional (low temperature-)sintering steps. This usually involved hand-operated hydraulic presses with inaccurate force and temperature control. The CompreDrive can be used to prepare samples using well-defined pressure and temperature steps, which allows for an actual optimization of preparation procedures. This can lead to more reproducible samples and experimental results.

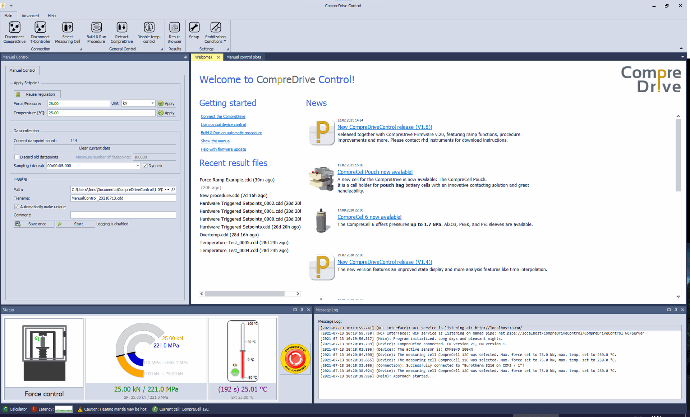

Modern user-interface

Control your CompreDrive comfortably using a comprehensive software package!

The CompreDriveControl software connects with both the CompreDrive as well as a temperature controller. It then offers all functionality required for manual control as well as automated measurements.

For automatic measurements CompreDriveControl offers a convenient procedure builder. Here you can define a series of setpoints that will be applied one after another. The running procedure can be synchronized with an electrochemical device via hardware or software (REST) triggers. This allows for e.g. triggering a measurement when the force and temperature are stable, and move to the next step once the measurement is complete. The measured force and temperature data can be logged to a file.

The manual control mode allows you to set the CompreDrive to a specific force and temperature setpoint. You can inspect the force and temperature as a function of time in a customizable plot and log the full data to a file. In manual control the CompreDriveControl software can also accept setpoints supplied via a REST API with a simple http interface. The same interface can also be used for reading the current force and temperature values as well as for triggering. For static measurements the closed loop control system can be deactivated after a manual setpoint is reached.

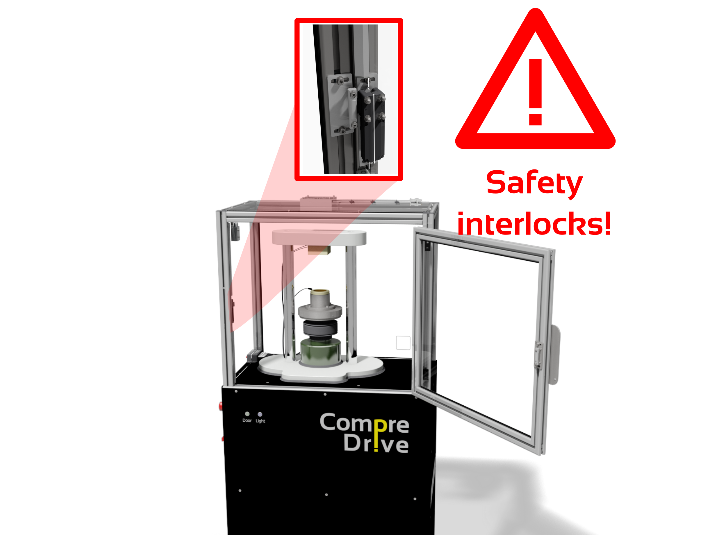

Reliable safety features

The CompreDrive is equipped with various hardware and software based safety features to prevent any injury to the user, or the CompreDrive itself.

All moving, or force bearing parts are inaccessible during operation, shielded by the safety glass housing equipped with an electromechanical door lock.

The control software verifies if every user input is within the device and cell specifications to prevent unapproved operating conditions.